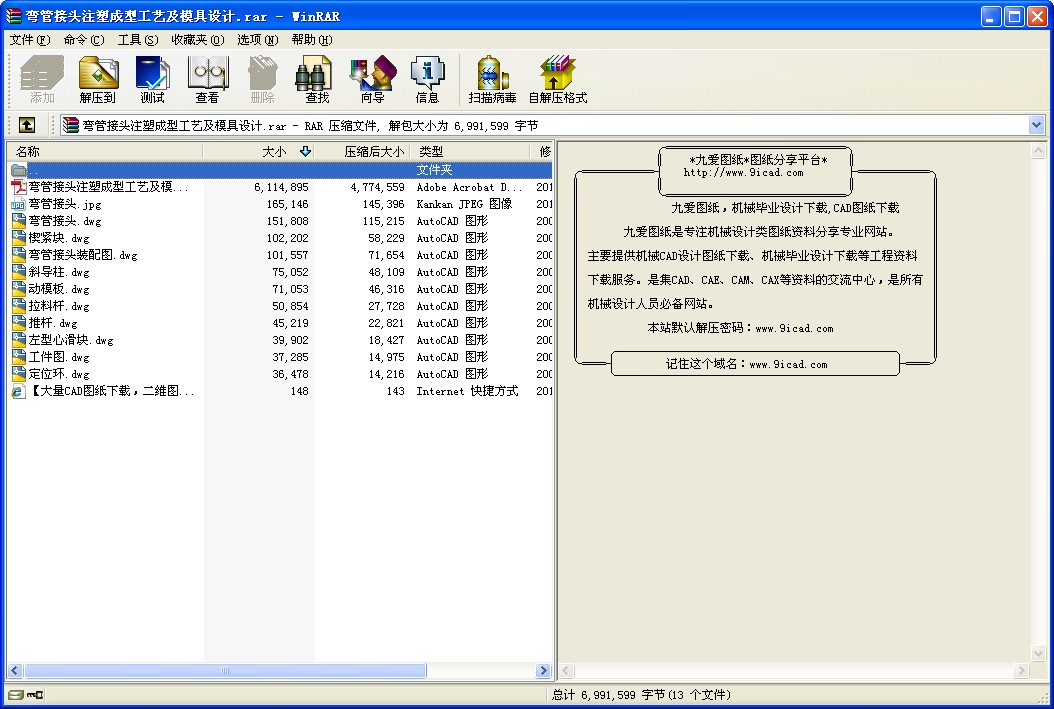

彎管接頭注塑成型工藝及模具設計

- 文件介紹:

- 該文件為 rar 格式(源文件可編輯),下載需要

20 積分

-

- 彎管接頭注塑成型工藝及模具設計

目錄

摘 要 ......................................................................................................................................................... I

Abstract ...................................................................................................................................................... II

第一章 緒論 ........................................................................................................................................... 1

1.1 塑料成型在工業生產中的重要性 ......................................................................................... 1

1.1.1 塑料及塑料工業的發展 ................................................................................................ 1

1.1.2 塑料成型在工業生產中的重要作用 ......................................................................... 1

1.1.3 塑料成型技術的發展趨勢 ........................................................................................... 2

1.2 塑料模具的分類 ......................................................................................................................... 2

第二章 塑件成型工藝分析 ........................................................................................................... 4

2.1 塑件分析 ...................................................................................................................................... 4

2.1.1 總體分析 ........................................................................................................................... 4

2.1.2 脫模斜度 ........................................................................................................................... 4

2.2 ABS性能分析 .............................................................................................................................. 5

2.2.1 使用性能 ........................................................................................................................... 5

2.2.2 工藝性能 ........................................................................................................................... 5

2.3 ABS的注射成型過程及工藝參數 ......................................................................................... 5

2.3.1 注射成型過程 .................................................................................................................. 5

2.3.2 注射工藝參數 .................................................................................................................. 6

第三章 模具結構形式的擬定 ...................................................................................................... 7

3.1 分型面的確定 ............................................................................................................................. 7

3.1.1 分型面的形式 .................................................................................................................. 7

3.1.2 分型面的選擇原則 ......................................................................................................... 7

3.1.3 本設計分型面的選擇 .................................................................................................... 7

3.2 型腔數目和模具結構形式的確定 ......................................................................................... 8

3.2.1 型腔數目的確定 ............................................................................................................. 8

3.2.2 模具結構形式的確定 .................................................................................................... 8

3.3 注射機型號的確定 .................................................................................................................... 8

3.3.1 注射量的計算 .................................................................................................................. 8

3.3.2 澆注系統凝料體積的初步估算 .................................................................................. 8

3.3.3 注射機的選擇 .................................................................................................................. 8

3.3.4 注射機相關參數校核 .................................................................................................... 9

第四章 澆注系統、冷卻系統和排氣系統的設計 ...........................................................11

4.1 澆注系統設計原則 ...................................................................................................................11

4.2 主流道設計 .................................................................................................................................11

4.2.1 主流道尺寸 .................................................................................................................... 12

4.2.2 主流道的凝料體積 ....................................................................................................... 12

4.2.3 主流道當量半徑 ........................................................................................................... 12

4.2.4 主流道澆口套的形式 .................................................................................................. 12

4.3 分流道設計 ............................................................................................................................ 13

4.3.1 分流道設計原則 ........................................................................................................... 13

4.3.2 分流道的布置形式 ....................................................................................................... 13

4.3.3 分流道相應參數的確定 .............................................................................................. 14

4.3.4 校核剪切速率 ................................................................................................................ 14

4.4 澆口的設計 ................................................................................................................................ 15

4.4.1 澆口形式及尺寸確定 .................................................................................................. 15

4.4.2 側澆口剪切速率的校核 .............................................................................................. 15

4.5 校核主流道的剪切速率 ......................................................................................................... 16

4.6 冷料穴的設計與計算 ............................................................................................................. 17

4.7 溫度調節系統 ........................................................................................................................... 17

4.8 排氣系統 .................................................................................................................................... 17

第五章 成型零件的結構設計及計算 .................................................................................... 18

5.1 成型零件的結構設計 ......................................................................................................... 18

5.1.1 型腔的結構設計 ........................................................................................................... 18

5.1.2 型芯的結構設計 ........................................................................................................... 18

5.2 成型零件材料的選用 ............................................................................................................. 18

5.3 成型零件工作尺寸的計算 .................................................................................................... 18

5.3.1 型腔尺寸計算 ................................................................................................................ 18

5.3.2 側抽芯凸模尺寸計算 .................................................................................................. 19

第六章 模架組合的選擇 ............................................................................................................... 21

6.1 決定模板尺寸的因素 ............................................................................................................. 21

6.2 模架的選擇 ................................................................................................................................ 21

第七章 合模導向機構的設計 .................................................................................................... 22

第八章 脫模推出機構的設計 .................................................................................................... 24

8.1 推出方式的確定 ....................................................................................................................... 24

8.2 推出位置、推桿數量和斷面形狀的設計 ......................................................................... 24

8.3 推桿復位裝置 ........................................................................................................................... 24

第九章 側向分型與側抽芯機構的設計 ............................................................................... 25

9.1 抽芯距與抽芯力的計算 ......................................................................................................... 25

9.1.1 抽芯距的計算 ................................................................................................................ 25

9.1.2 抽芯力的計算 ................................................................................................................ 25

9.2 斜導柱的側向分型與側抽芯機構的設計要點 ............................................................................ 26

9.2.1 斜導柱的設計 ................................................................................................................ 26

9.2.2 滑塊的設計 .................................................................................................................... 28

9.2.3

摘 要:

塑料工業是當今世界上增長最快的工業門類之一,而注塑模具是其中發展較快的種類,因此,研究注塑模具對了解塑料產品的生產過程和提高產品質量有很大意義。 本設計介紹了注射成型的基本原理,特別是單分型面注射模具的結構與工作原理,對注塑產品提出了基本的設計原則;詳細介紹了冷流道注射模具澆注系統、溫度調節系統和頂出系統的設計過程。彎管接頭具有兩個方向的側向抽芯。本設計分析了彎管接頭的成型工藝,確定了工藝方案,介紹了模具結構和主要模具零部件的設計,分析了本模具結構及產品質量上的可行性及可靠性。 關鍵詞:彎管接頭;注射模;成型工藝;側向抽芯

Class x, Material Processing and Controlling Engineering, School of Mechanical Engineering, xx University. Xx, xx, xx Province, P.R.CHINA

Abstract:

Now The plastic industry is one of the quickest developing industry classes in the world, and the injection mould is one of the developing type. Therefore, there is great significance to study the injection mould to understand that the plastic of production process and improve the product quality. The basic principle of injection molding, specially the operating principle and the structure of the single-parting-surface injection mould is introduced. The design of the runner system, temperature control system and the ejection is introduced in detail. The technology for forming the elbow joint is analyzed and a better technics is decided .The elbow joint has two side core-pulling in different directions. The structure of the mould and the designing of the main parts are introduced. The feasibility and reliability in mould structure are discussed to guarantee the quality of the product.

Keywords: elbow joint; injection mould; forming process; side core-pulling

該塑件如圖2-1所示,材料為ABS,流動性能為中等,溢料間隙為0.05mm,塑件最大壁厚為4mm,最小壁厚為1.5mm,未注圓角為R3mm,精度等級為SJ1372-78中4級精度,屬于中等精度塑件。經分析,該塑件可用注塑成型,但模具設計時應考慮兩個方向的側抽芯問題。 圖2-1 彎管接頭

2.1.2 脫模斜度

ABS屬于非結晶型熱塑性塑料,其成型收縮率較低,一般介于0.4%~0.7%,結合該塑件的特點,不需要設計脫模斜度。

5

2.2 ABS性能分析

2.2.1 使用性能

ABS是樹脂的剛性與橡膠的彈性相結合的一種廣泛使用的工程材料,它不僅具有韌、硬、剛相均衡的優良力學性能,而且耐化學藥品性好、尺寸穩定性好、表面光澤度高,且原料豐富。廣泛用于機械、電器零件、辦公用品、日用品等各個領域。

2.2.2 工藝性能

...

文檔留言 共有條評論

熱門關鍵詞:

熱門關鍵詞:

豫公網安備 41072402000322號

豫公網安備 41072402000322號